Glass is Our Unique Specialty

Repair Services

- Repair of scratched glass

- Repair of vandalized glass / by acid and or scratchitti

- Repair of grinding or welding slag damage to glass

- Repair of stains on glass

- Repair of chemically etched glass

- Repair of acid rain denigrated glass

- Repair of wear & tear degradation over time

- Removal of bonded mineral stains from glass

- Safe removal of construction debris from glass

- Glass includes mirrors & some porcelain materials

Other Unique Glass Services

- Cleaning stains and debris from sand blasted or frosted finished glass

- Cleaning of silicone debris from sand blasted or frosted finish glass

- Application of “easy clean” polymer coatings to glass

- Application of clear graffiti film, safety and security film and decorative films

Other Services

- Marble and natural stone restoration, refinishing and protection

- Metal restoration and refinishing

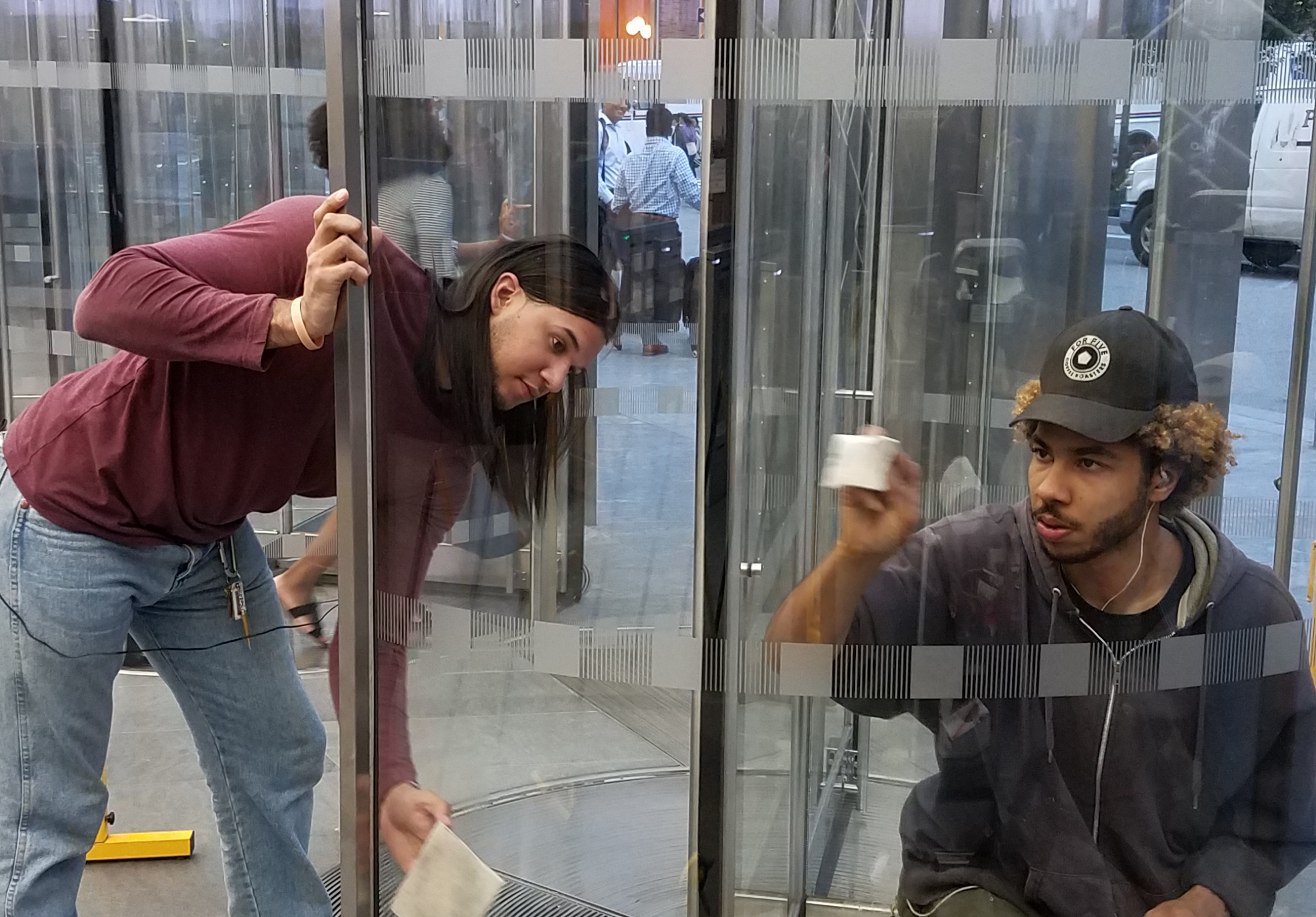

Glass Restoration Process

Our system and process is proprietary and the following information is being provided in summary form. Additional technical details are available on request.

Equipment & Materials

Variable Speed Grinding Tool

Vacuum & Dust Shroud

Abrasive Pads

Polishing Felt Pad

Cerium Oxide Polishing Compound

Process

Abrasive pads are employed, in a dry process, in sequence starting from the roughest grit necessary, as determined by the degree of damage to the surface.

Seven to eight abrasive steps followed by one final nonabrasive polish / finishing step to include felt pad, cerium oxide and minimal water.

Abrasive work is performed with care to not overheat the surface. Depending on the surface area being worked on, to maintain a temperature in the desired range may require stopping from time to time to let the surface cool down.

Following the abrasive sequence, a polishing process is employed using a felt pad and a cerium oxide mixture applied to the pad and the surface with water at a controlled rate of rpms.

Work is performed in a meticulous grid pattern, “feathering out” the removal of surface damage to maintain the best possible optical quality of the glass and minimize any optical variations. In some cases, the best result may include leaving a small remnant of the damaged area where the damage is very deep so as to achieve the best possible overall outcome.

Surrounding areas are protected from work in process as necessary and personnel employ necessary personal protection.

Note: Our company has specialized in this work and evolved our system since 2004. Important to the quality of results is the skill and experience of the mechanics. Our master mechanics have been performing this work exclusively and have experience averaging 10+ years.

Note: Our company has specialized in this work and evolved our system since 2004. Important to the quality of results is the skill and experience of the mechanics. Our master mechanics have been performing this work exclusively and have experience averaging 10+ years.

551 Fifth Avenue,

Suite 2200

New York, NY 10176

Office: 212.972.8847

Hotline: 917.282.4934

551 Fifth Avenue,

Suite 2200

New York, NY 10176

Office: 212.972.8847

Hotline: 917.282.4934